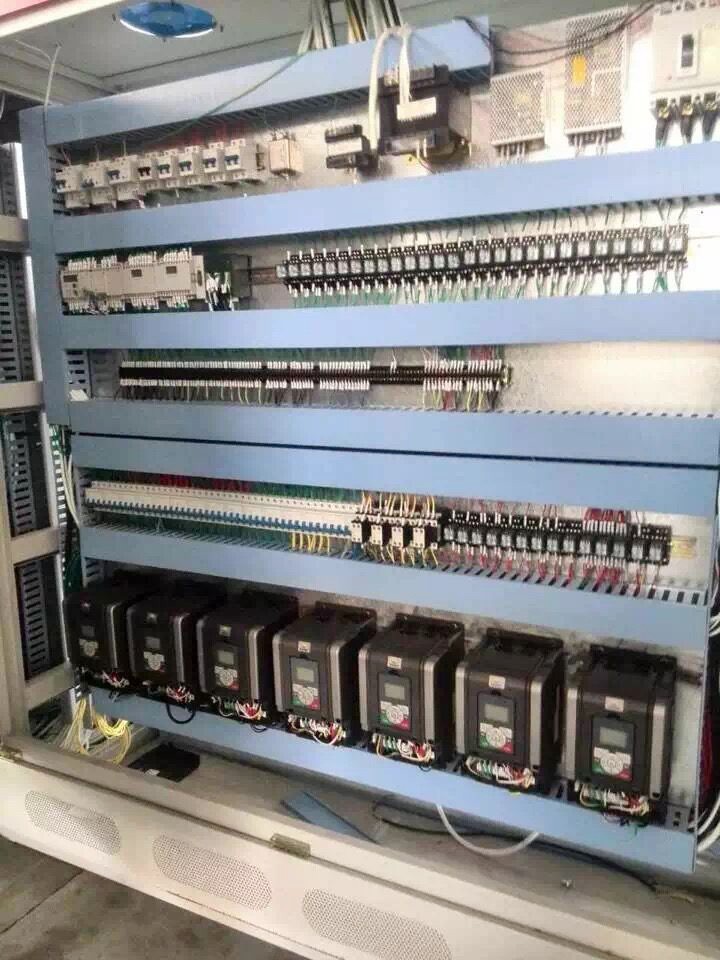

Intaglio press control system(seven motor)

Intaglio press is generally composed of loading, inking, embossing, paper feeding (including folding) and other mechanisms.

Working process:

Firstly, the text/image to be printed is made into a plate mounted on the press.

Secondly, ink is then applied to the plate by workers or by intaglio press, and then transferred to paper, textiles, metal plates, plastic, leather, wood, glass, and ceramics, thereby creating a copy of the plate.

Requirements for the press control system:

Accurate color registering, even inking, rich color layers,

High printing precision, constant tension.

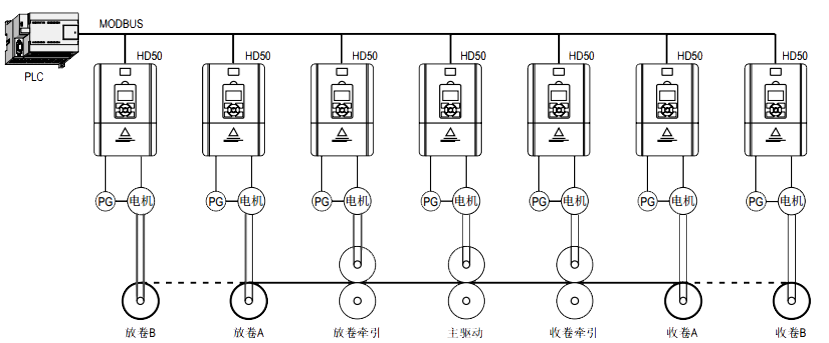

Hpmont intaglio press control system(seven motor)

Solution features:

1. Rapid response of winding and unwinding, accurate color registering.

2. The system of winding is controlled by HD50-T inverter with tension-free torque control and closed loop. IPLC can be also used to calculate the tension and give the output torque to the inverter. At this time, the inverter only needs to be set the torque control.

3. The system of unwinding can be controlled by the tension control function of the inverter, and can also receive the calculated torque signal given by IPLC. At present, magnetic powder brake is used in the unwinding part, and the control system can calculate the unwinding diameter of the roller according to the photoelectric signal or the encoder signal.

Applications: